What is a Step-up transformer and how does it work?

As its name indicates, the step-up transformer is a device that steps-up or controls the output voltage much more extensively than its input voltage while keeping the current steady without any variables. They are mainly used in power generation stations and power transmission applications.

Table of contents

1. What is a Step-up transformer?

2. Construction of the Step-up transformer

a. Core

b. Winding

3. Working of the Step-up transformer

4. Advantages of the Step-up transformer

5. Disadvantages of the Step-up transformer

6. Applications of the Step-up transformer

7. Factors to keep in mind when choosing a step-up transformer

1. What is a Step-up transformer?

The transformer is an electrostatic device that converts electrical energy (from the primary winding) into magnetic energy (in the transformer’s magnetic core) and back into electrical energy (on the secondary side of the transformer).

The step-up transformer is a type of transformer with the function of converting low voltage (LV) and high current from the transformer's primary side to high voltage (HV) and low current value on the transformers’ secondary side.

2. Construction of the Step-up transformer

The step-up transformer is composed of windings, transformer enclosure, and core.

a. Core

The design of the transformer core is made of highly waterproof material.

This material allows the magnetic pass to run through with fewer losses. The core material contains a higher permeability than the neighbouring air.

As a result, this material will limit the magnetic field lines within the main material. In this way, the performance of the transformer can be increased by minimizing losses.

The magnetic core allows the flux to run within it and leads to root damage, such as eddy current loss due to hysteresis.

Therefore, a low-conductivity and hysteresis material was chosen to make the core similar to ferrite or silicon steel.

The transformer core is laminated to keep eddy currents to a minimum. This can prevent core warming.

When the core heats up, a significant amount of electrical energy is lost. And the performance of the transformer may be reduced.

b. Winding

The windings in the cascading transformer will help transmit the current to the transformer.

These windings are specially designed to keep the transformer cool and withstand the test and operating conditions.

The gauge thickness is used on the primary side, and its number of turns is smaller than on the secondary.

Similarly, a thin coil is used in the secondary, and it turns more than the primary.

It is designed in such a way that the primary can carry less than the secondary supply voltage.

The material used in the transformer windings is usually copper or aluminum.

Aluminum is cheaper than copper, but the life of a transformer can be extended by using copper.

There are different types of coatings available in transformers that can reduce eddy currents, such as type EE and type EI.

3. Working theory of the Step-up transformer

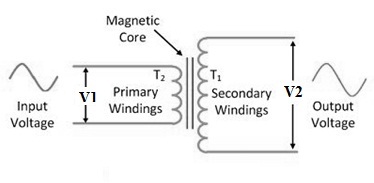

A symbolic representation of the step-up transformer is shown below. In the following figure, the input and output voltages are represented by V1 & V2, respectively. The turns on the windings of the transformer are T1 & T2. Here the input coil is primary while the output is secondary.

The output voltage is higher than the input voltage because the number of turns on the primary winding is less than the secondary. Once alternating current flows in the transformer, then-current flows in one direction, stopped, and reversed to flow in the other direction.

Electric current will create a magnetic field in the area of the coil. The direction of the magnetic poles will be changed once the current changes direction.

The induced voltage in the coils adopts a magnetic field. Likewise, the voltage will be generated in the secondary coil in a moving magnetic field called mutual induction. Therefore, the alternating current in the primary coil creates a moving magnetic field to induce the secondary voltage.

The primary relationship between the number of turns in each winding and the voltage can be given using this step-up transformer formula.

V2 / V1 = T2 / T1

Where ‘V2’ is the voltage in the secondary coil

‘V1’ is voltage is the primary coil.

‘T2’ turns on the secondary coil.

‘T1’ turns on the primary coil

4. Advantages of the Step-up transformer

The advantages of step-up transformers include the following.

- They are used in residential and commercial places.

- Power Transmitter

- Maintenance

- Efficiency

- Continuous Working

- Quick Start

5. Disadvantages of the Step-up transformer

The disadvantages of step-up transformers include the following:

- It requires a cooling system

- Works for Alternate Current

- The size of these transformers is enormous.

6. Applications of the Step-up transformer

The use of Step-up Transformers includes the following.

- These transformers are used in electronic equipment such as Inverters & Voltage Stabilizers for low to high voltage stability.

- It is used to distribute electrical energy.

- This transformer is used to change the high voltage in power transmission lines generated by generators.

- This transformer is also used to make electric motors running, X-ray machines, microwave ovens, etc.

- It is used to enhance electrical and electronic equipment.

7. Factors to keep in mind when choosing a step-up transformer

There are different factors to check while choosing a step-up transformer.

- Transformers Efficiency

- Number of Phases

- Transformers Rating

- Cooling Medium

- Material of Windings

MBT is a brand of transformer products that have a high reputation in the market. With the strength of experience and technological lines in manufacturing, a good team of engineers, skilled technical workers, and abundant customer partners in many areas, so we are always leading about quality of service and price.

We design, manufacture, and supply all kinds of electrical transformers with a dedicated project manager and a 24-month guarantee from dispatch.

With the business motto: "A satisfied customer is the best business strategy of all," and over 11 years of experience in transformer design and manufacture. We, MBT, are confident of being the best transformer manufacturer in Vietnam.

Contact immediately +84913 006 538 or email: info@mbt.vn for a free consultation and support and receive the most preferential quotation.