Amorphous transformer | MBT Electrical Equipment JSC

What is an Amorphous transformer, and how it works?

An electrical transformer is an essential device in the distribution and transmission system of electricity in the national grid electricity system. Along with the development of technology, the transformer manufacturing industry has also overgrown in recent years. Amorphous transformers were born with many outstanding features that outperformed those of the same type: saving operating costs, reducing CO2 emissions into the environment, increasing product life cycle, …

Table of Contents

1. What is an Amorphous Core Transformer?

3. Structure of the Amorphous transformer

4. Processing cores from amorphous transformers

5. The amorphous transformer manufacturing costs

6. The benefits of amorphous metal cores

7. Advantages and disadvantages of amorphous transformers

8. Amorphous Transformer Quotes

1. What is an Amorphous Core Transformer?

An amorphous core transformer is a core transformer made of amorphous steel. The most significant benefit of an amorphous transformer is that the amorphous steel has lower hysteresis loss. In other words, transformers made of this amorphous steel waste less energy (in the form of heat) during the magnetization and demagnetization of the core.

2. What are Amorphous Metals?

The molten alloys are rapidly cooled at a rate above 1 million ° C per second to produce amorphous metal. Amorphous metal is a metal that has no crystalline structure, which imparts different properties in different directions. In other words, this metal has a random atomic structure, which makes it extremely useful in transformer applications. It has both high permeability and excellent soft magnetic properties.

Amorphous metals are used in transformers such as pole transformers and industrial transformers with a predominantly iron composition. Compared with conventional materials such as silicon steel, amorphous metal materials have small no-load losses (iron losses), equal to 1/5 of silicon steel. Therefore, they make a significant contribution to energy conservation.

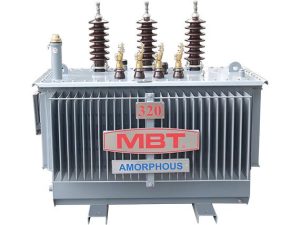

3. Structure of the Amorphous transformer

The amorphous transformer structure is the same as an ordinary transformer's general structure. The main difference is that the core of a transformer is made from amorphous metal.

The structure of the amorphous core specifies the windings of rectangular construction. Once the design has been established, the magnetic circuit's rectangular profile is resistant to short-circuit stresses.

Amorphous transformer magnetic core

The magnetic circuit consists of pre-assembled single-phase coil sheets, incubated at about 3500 ° C. Once the magnetic circuit has been installed, it will stiffen and act as mechanical support on which all the transformer elements rest.

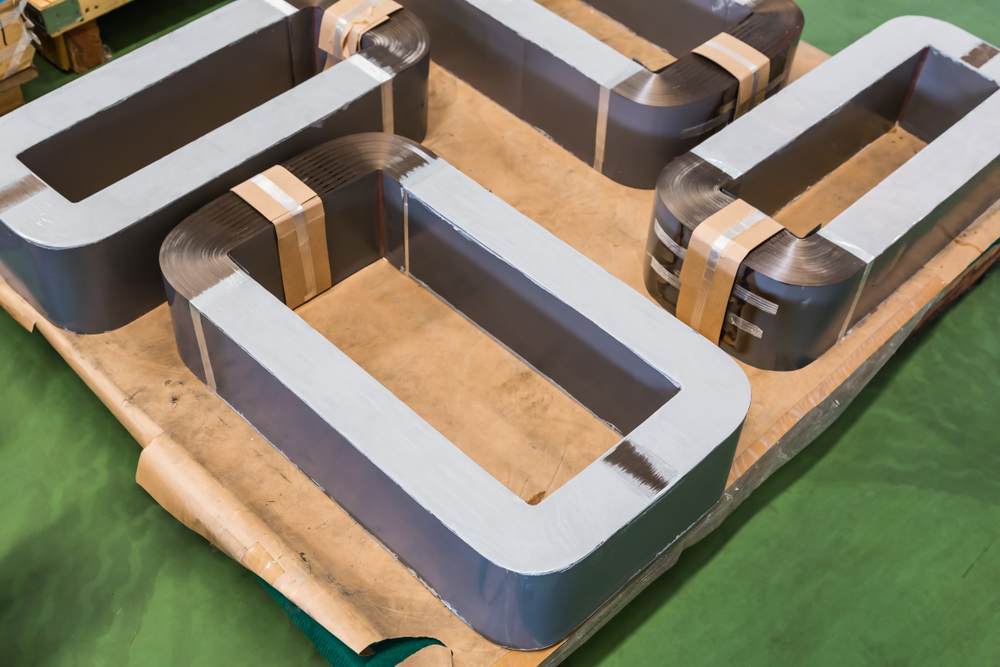

4. Processing cores from amorphous transformers

Because the amorphous material is so thin, to avoid the appearance of core debris by applying the following procedure:

- Epoxy coating is covered on both sides of the assembly core except in the coil open position. As a result, the individual core layers become a solid block and stay in place. Additionally, the core assembly is wrapped with CRGO panels to provide mechanical strength.

- FRP (composite resin) insulation is provided between the low-voltage coil and the core to reduce force's effect on the core assembly during the transformer operation. The forces generated during transformer operation are absorbed by FRP, thereby reducing the force on the core.

For transformers with a rating above 250kVA, the silver paper should be used for the LV (low voltage) windings. This reduces the axial force and increases the short-circuit resistance of the transformer. We use epoxy diamond dot paper (EDD) as interlayer insulation for LV & HV (low pressure and high voltage) coils.

EDD paper is created using a heat-resistant plastic in the form of square dots on both sides of the kraft paper. The pattern of the plastic dots ensures that there is enough space between them for oil impregnation. The coils produced by this process are dried in an oven in which the plastic melts and hardens. Through this process, the layers are glued together, and the complete coil becomes a solid block.

In Amorphous transformers, the presence of steel core debris is inevitable. During the manufacturing process, the core overlap area is located at the bottom, and the compartment layout is provided for the core. As a result, any core debris that has formed is collected in the workpiece containment system and does not float in the oil.

5. The amorphous transformer manufacturing costs

An amorphous core transformer's total cost is approximately 20% to 30% higher than that of a CRGO Core Transformer.

Why does the amorphous core have a rectangular cross-section?

Several attempts have been made to reduce the cost of CRGO core transformers by prioritizing the circular cross-section of the CRGO core instead of the rectangular cross-section.

For a circular cross-section of the core, the average length of the rotation is reduced, so the mass of copper used in the coil decreases; thus, the transformer's cost is reduced by reducing winding costs.

Manufacturers distributing amorphous transformer cores are very limited for two reasons:

- The high cost of materials

- Amorphous transformer cores are very brittle and fragile

Because of its limited brittleness, in amorphous core transformers, manufacturers use a square or rectangular cross-section of the core.

6. The benefits of amorphous metal cores

An amorphous metal core transformer's great benefit is that the amorphous steel core has a lower hysteresis loss. Since there is no atomic arrangement law, the small energy loss (delay) when the induced current flows through the iron core.

Non-crystalline structure and random arrangement of atoms give low magnetic fields and high resistivity. Due to the magnetic field, low delay, and eddy currents with high resistivity, losses are minimal. As the core loss of metal alloy amorphous reduced by 42% and the magnetization current is 53%.

Besides, eddy current losses are reduced because of a thickness of approximately 0.03 mm, about 1/10 of silicon steel. The no-load loss rating is 1/4 to 1/3 of transformers that use traditional silicon steel for the core. By the way, the temperature in this amorphous steel core is low, which will significantly reduce the amount of air CO2 released into the environment.

Two types of energy losses are inherent in a distribution transformer's operation: Load losses (copper losses) vary depending on the transformer load, and no-load losses (iron losses) occur out in a magnetic field. When this is replaced with amorphous metal, the transformer's core is reduced by up to 75%.

7. Advantages and disadvantages of amorphous transformers

a. Advantages of amorphous transformer

In the past, awareness of global warming and gas emissions was not as concerned as today, and the concept of "Energy Efficiency" was not a priority in transformer design. The Amorphous Core Transformer is an alternative to conventional transformers. It is mainly used to reduce no-load losses compared to conventional core transformers, thereby significantly saving energy.

- Save up to 75% energy

- Reducing CO2 and SO2 waste

- The magnetization flow is reduced

- Decreased core temperature rise

- Save accumulated energy costs

- The lifetime of the transformer is increased (25 – 30 years)

- Provides the key to improving utility economics and increasing energy efficiency efforts

b. Disadvantages of amorphous machines

Besides these outstanding advantages, amorphous transformers also have the following disadvantages:

- The material is fragile 0.03 mm, so it isn't easy to handle

- Cannot repair in place

- Amorphous metal is brittle, so be careful during assembly, not too strong.

- Specialized lines of machinery and technological equipment are needed to manufacture and assemble the core

- Only a few enterprises are capable of manufacturing this type of transformer

The manufacturing process for the amorphous steel core:

8. Amorphous Transformer Quotes

MBT is a brand of transformer products that have a high reputation in the market. With the strength of experience and technological lines in manufacturing, a good team of engineers, skilled technical workers, and abundant customer partners in many areas, so we are always leading about quality of service and price.

We design, manufacture, and supply all kinds of electrical transformers with a dedicated project manager and a 24-month guarantee from dispatch.

With the business motto: "A satisfied customer is the best business strategy of all," and over 11 years of experience in transformer design and manufacture. We, MBT, are confident of being the best Transformer manufacturer in Vietnam.

Contact immediately +84913 006 538 or email: info@mbt.vn for a free consultation and support and receive the most preferential quotation.