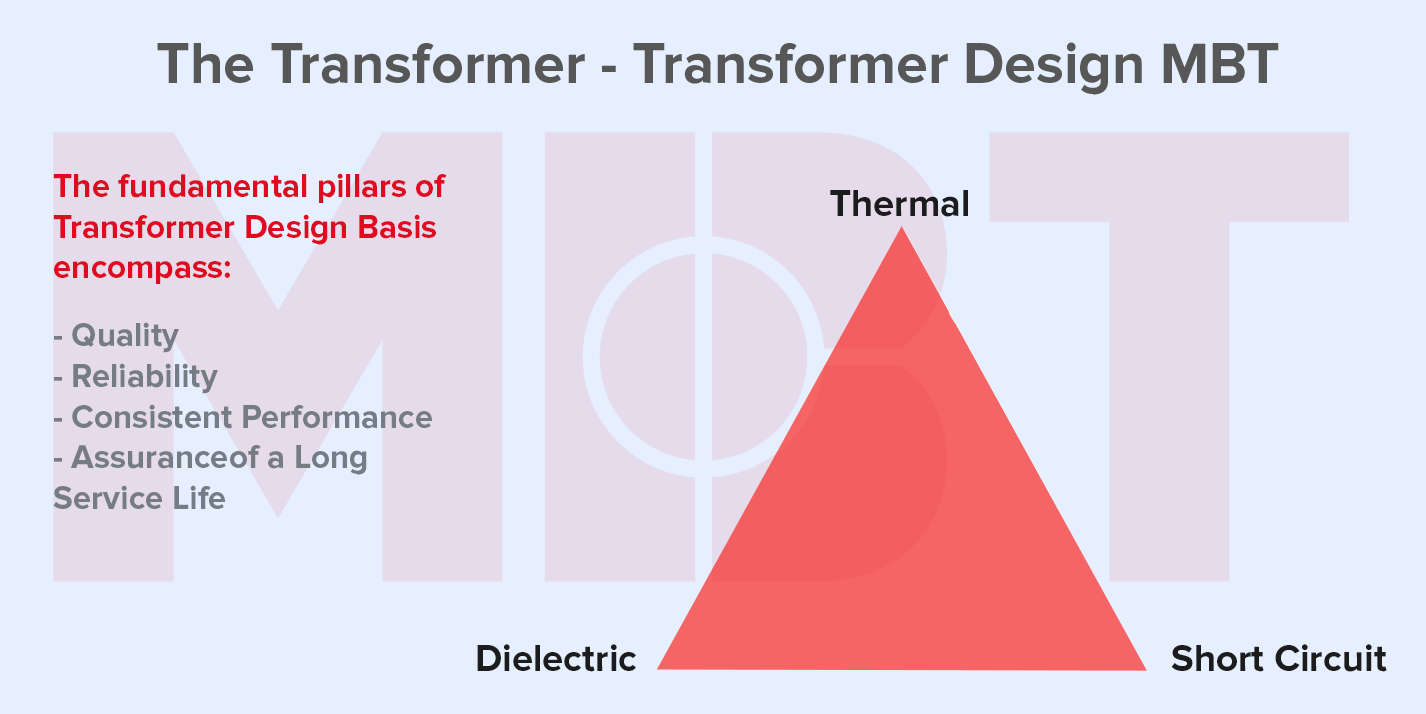

Transformer Manufacturing Materials

Transformer Manufacturing Materials: Which is the best?

On behalf of modern machinery and equipment systems, it also depends on input materials to have a good transformer. Materials for manufacturing transformers are always strictly controlled by manufacturers, ensuring suitable quality, quantity, and type under domestic and international standards.

To learn materials for transformer manufacturing, we first need to know about the structure of the transformer. The general basic construction of the transformers (or parts of the transformer) has three parts: steel core, coil, and machine cover.

Steel core: used to conduct flux, made of good magnetic conductive materials. Transformer cores are laminated to reduce eddy current loss. Consists of many thin steel sheets (another word that is laminated core), the outer surface with insulating paint are assembled into the steel core. The steel core consists of 2 parts, including Pillar and Gong.

The steel cores are being assembled by MBT's workers

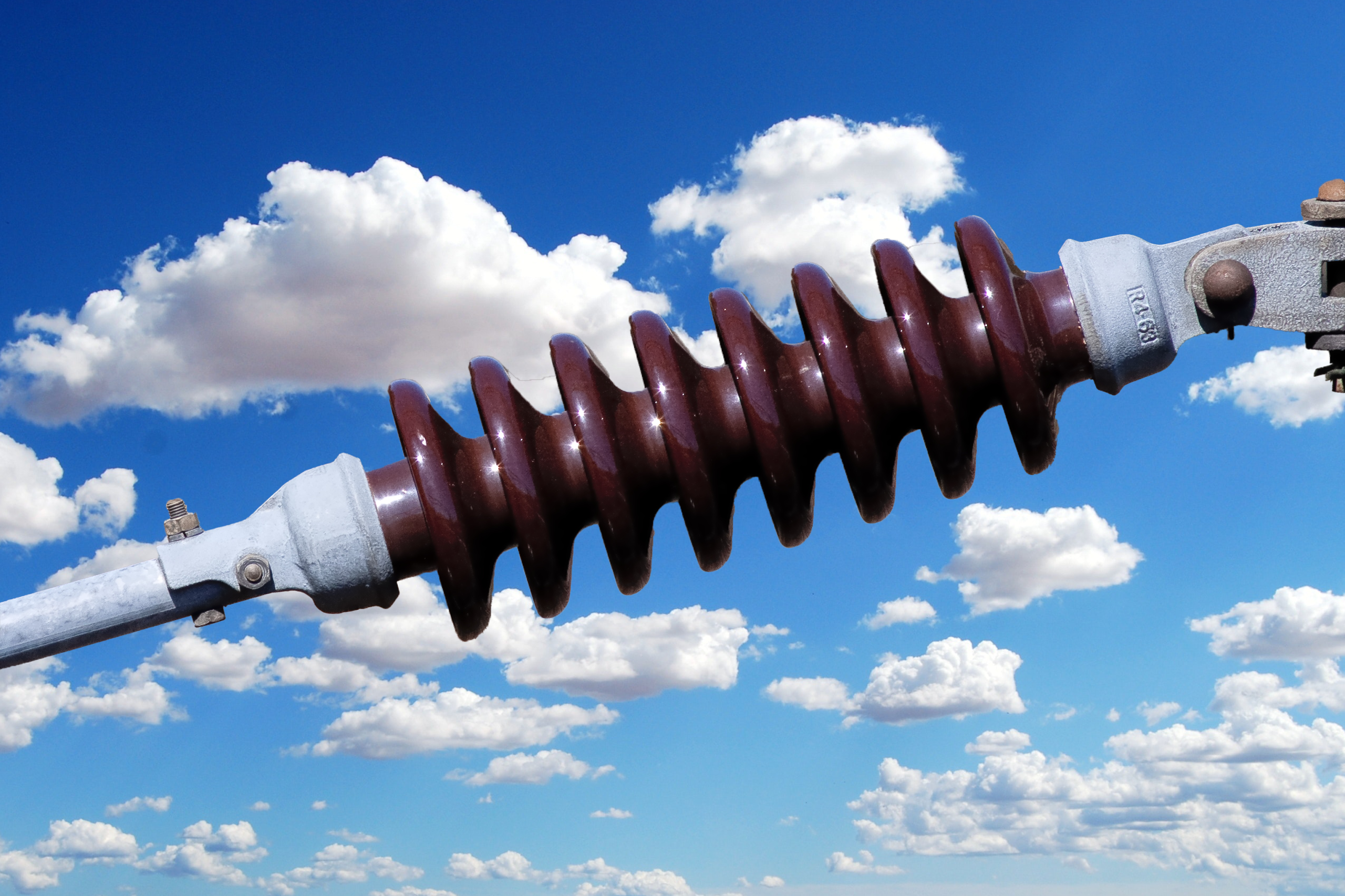

Coil: used to receive energy in and transmit energy out. Usually made of copper or aluminum, the cross-section is circular or rectangular and insulated. The number of turns of the two coils varies, depending on the transformer duty.

.jpg)

The coils inside the transformer

Machine cover: The case types depend on the kind of transformer but is usually made of steel or thin sheet, which is used to protect the internal components. The case includes the barrel and lid.

-

The barrel enhances insulation and heat dissipation.

MBT's steel transformer barrel

-

The lid is used to cover the barrel and contains some essential transformer parts.

The lid and other accessories for the transformer

.jpg)

Inside the MBT's transformer

Related post: Transformer structure

Table of comparison of transformer production material

| STEEL CORE | |

| Consists of many thin-rolled electrical engineering steel sheets | |

| COIL | |

| COPPER | ALUMINUM |

|

Good electrical conductivity, limiting oxidation, increasing durability, the longevity of the machine and reducing energy consumption The price is 3-time more than Aluminum Coil

|

Conductive electricity is only 60% of copper coil, the criteria for durability, power consumption, the longevity of the machine is also lower than copper wire one. Aluminum wire is reduced by more than 30% by weight compared to copper wire.

|

| CASE | |

| STEEL | TOLE |

|

The highest price, the heaviest cover. In return, the machine is protected at the maximum.

|

Prices are average, lighter than steel cases. Ability to protect the machine at a good level.

|

The transformer is the key product of MBT Electrical Equipment Joint Stock Company (MBT). Our company is proud to be the leading manufacturer and supplier of prestigious transformers in Vietnam with more than 20 years of experience in transformer research and production. The company's employees are highly qualified. With modern technology equipment and machines, MBT's products and services have long been highly appreciated by the market.

With the business motto: "Quality nurtures reliability", customers who come to MBT will always receive products with high quality, reasonable prices, fastest delivery time and best warranty service.

Contact now +84 913 006 538 for free consultation support and receive the most preferential transformer quotation.

.jpg)