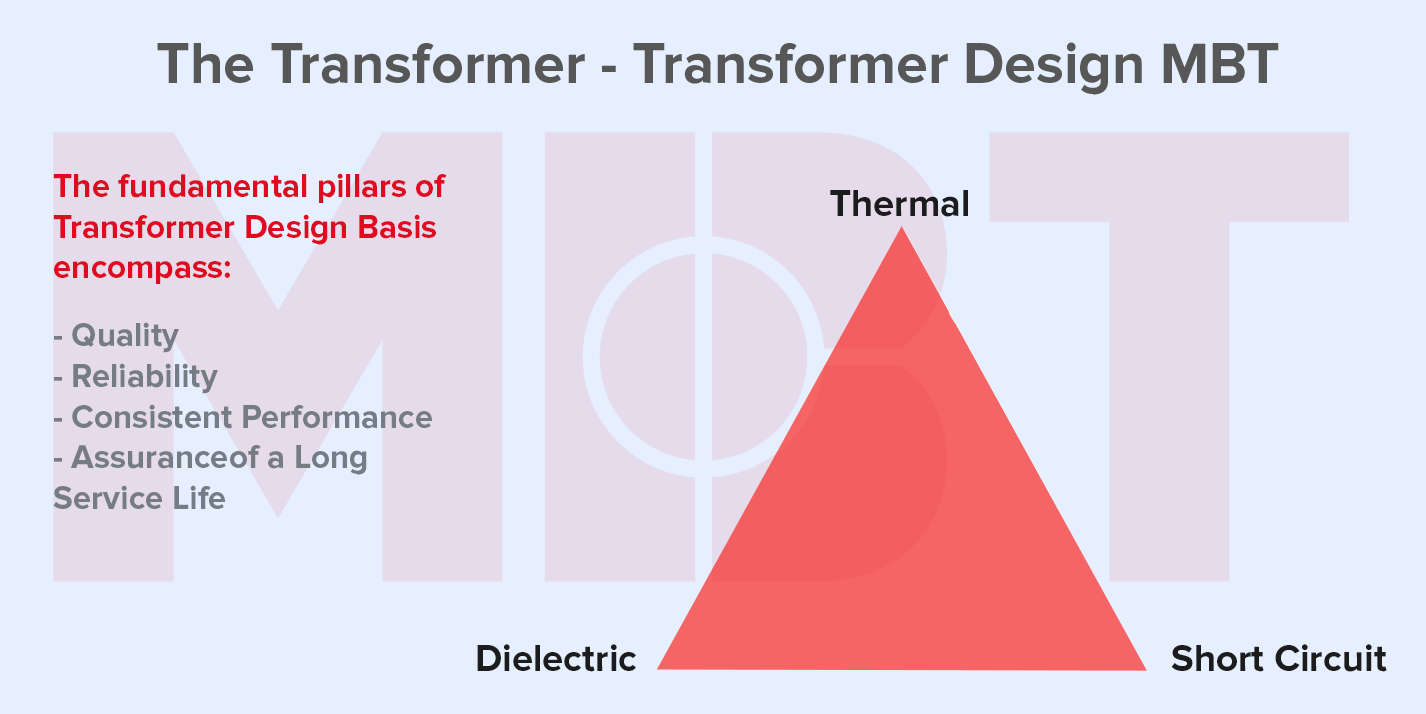

Dry-type transformer construction- MBT Electric

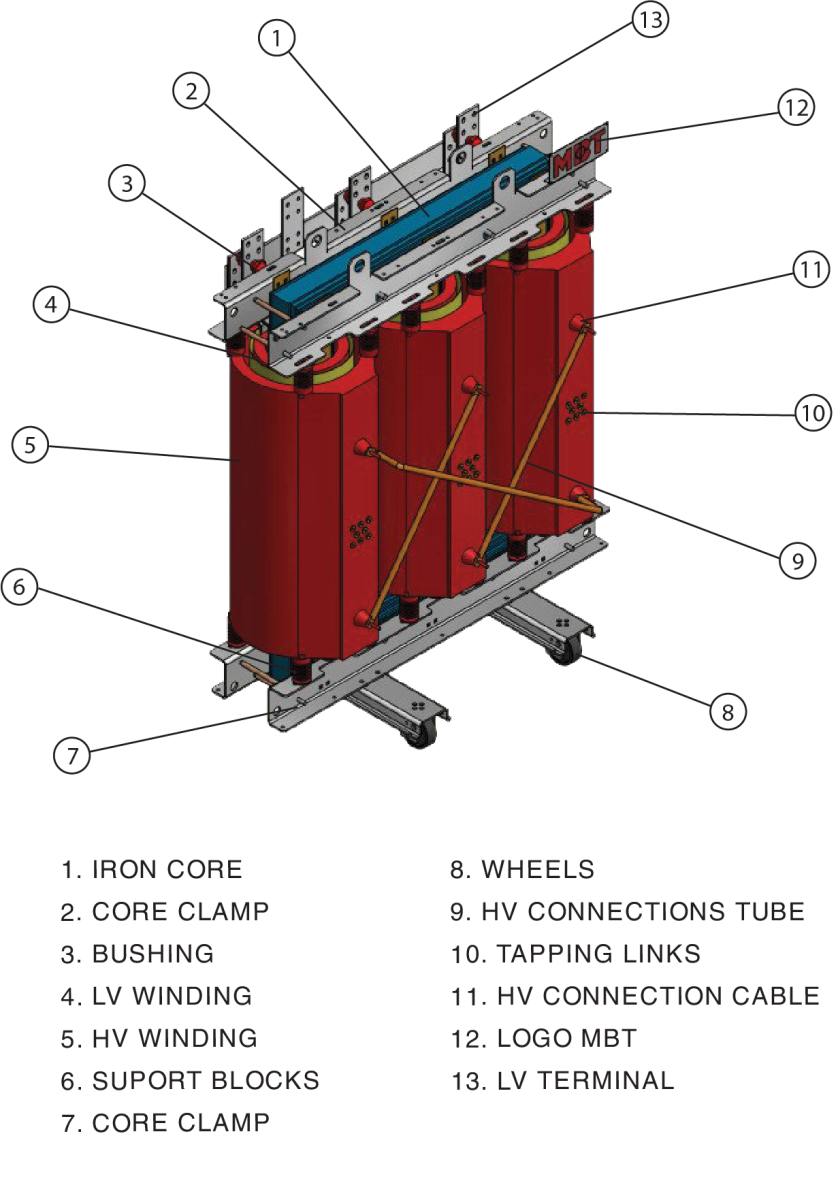

What is a dry transformer?

Unlike liquid-filled transformers, dry transformers do not incorporate liquid to dissipate excess heat and meet temperature classification requirements. Instead, the windings in a dry type transformer are made of a gaseous or dry insulating medium. Please see the picture below to see all the parts of a dry type transformer.

Image1: Dry-type transformer construction

Image1: Dry-type transformer construction

How many types of dry-type transformers

There are two types of dry-type transformers:

-

Cast Resin Dry Type Transformer (CRT) (Imange 2)

-

Vacuum pressure Impregnated Transformer (VPI) (Imange 3)

Image 2: Cast Resin Dry Type Transformer (CRT)

Image 3: Vacuum pressure Impregnated Transformer (VPI)

There are some typical parts of dry-type transformer:

Dry Type Transformer Taps – Dry type transformer construction

The transformer can be equipped with voltage taps in the high-voltage winding. Normally, two taps above and two below rated voltage are provided, giving a total induced voltage range of 10% (ANSI/IEEE, 1981 [R1989]; ANSI/IEEE C57.12.52-1981 [R1998] ).

Cooling Classes for Dry-Type Transformers – Dry type transformer construction

Cooling class designations for the US and Europe are shown in Table 2.5.1. The cooling classes for dry type transformers are as follows (IEEE, 100, 1996; ANSI/IEEE, C57.94-1982 (R-1987)):

Ventilation – Ambient air can circulate, cooling the transformer core and windings

No ventilation – No intentional circulation of outside air through the transformer

Hermetic – Self-cooling transformer with sealed enclosure

Self-Cooling – Cooling by natural air circulation

Air cooler – Forced recirculation air cooling

Self-Cooling / Forced Cooling – Rated natural circulating cooling and forced circulation cooling by wind.

.png)

Winding Insulation System

It is common practice to use resins or varnishes to seal or coat dry-type transformer windings to protect against adverse environmental conditions that can cause transformer winding deterioration. Insulating means for primary and secondary windings are classified as follows:

Molded Coil – The coil is reinforced or placed in a mold and molded in plastic under vacuum pressure. Lower sound levels are achieved when the coil is wrapped in solid insulation. Fill the coil with resin under vacuum to eliminate gaps that can cause halos. With solid insulation, the coil has outstanding short-circuit and mechanical strength, and is impervious to moisture and contaminants.

Vacuum Pressure Enclosure – The coil is embedded in the plastic under vacuum pressure. Wrapping the coils in plastic under vacuum conditions eliminates gaps that can cause halos. The coil has excellent mechanical and short-circuit strength and protects against moisture and contaminants.

Vacuum Impregnated – Coil is impregnated with varnish under vacuum pressure. An impregnated coil protects against moisture and contaminants.

Coated – The coil is dipped with varnish or turpentine. A coated coil provides multiple layers of protection against moisture and contaminants for application in moderate environments.

Below are two pictures of the dry-type transformer assembly.

Accessory

Coil temperature indicators can be equipped with contacts to provide indication and/or warning of coil temperature approaching or exceeding maximum operating limits. For sealed dry type transformers, gas pressure switches may be equipped with contacts to provide indication and/or warning of gas pressure deviation from the recommended operating pressure range.

Surge Protection

For transformers exposed to lightning or other surge voltages, the protective surge arrester shall be compatible with the transformer's basic lightning impulse insulation level, BIL.

The length of the conductor connecting the bushings of the transformer to the arrester – and from the arrester earth to the neutral – shall be the minimum length to eliminate induced voltages in the ground wire and earth current ( ANSI). -IEEE, C62.2-1987 [R1994]).

A lower BIL level may be applied when the surge arrester provides adequate protection. At 25 kV and above, a higher BIL level may be required because of overvoltage contact or for a higher margin of protection (ANSI/IEEE, C57.12.01-1989 [R1998]).

Access for more information:

If you need quotation or cosultation, contact us with information below:

– Phone number/whatsapp: +84 913 006 538

– Mail: info@mbt.vn

– Address: Song Cung Industrial Zone, Dong Thap Commune, Dan Phuong District, Hanoi, Vietnam.