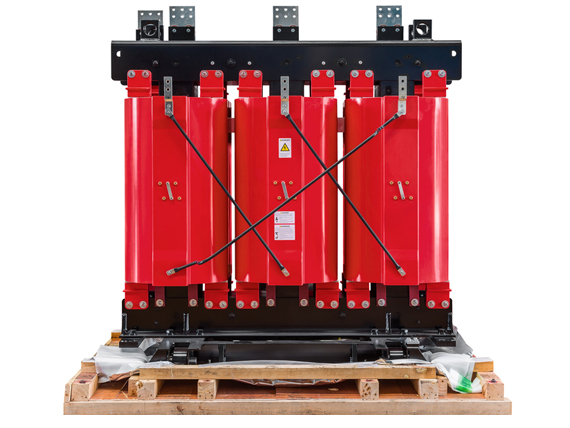

CAST RESIN TRANSFORMER

Cast resin transformer has another name that is dry-type transformer. They are the type of distribution transformer not use liquid to cool the coil but by air.

Maybe you are searching for the advantages and disvantages of cast resin dry-type transformers. You want to find complete information about their appliance to choose the right cast resin transformer for your factory. So today, we will show you the advantages as well as disadvantages of this machine.

Table of content

Some advantages of cast resin transformer

1. Cast resin transformers are self-extinguishing and low fire hazard

3. Safe and environment friendly

4. Low-cost installation and lower load losses

6. High short-time overload capacity

Some disadvantages of cast resin transformer

Cast resin transformer of MBT

SOME ADVANTAGES OF CAST RESIN TRANSFORMER

1. Cast resin transformers are self-extinguishing and low fire hazard

The transformer's insulation consists of an epoxy resin and quartz powder mixture (an eco-friendly material). They prevent the winding from fire. They are almost maintenance-free, so you don’t need to buy costly fire extinguishing equipment. Moreover, the cast resin transformer will also not produce toxic gases, not even effected by arcing.

2. Zero oil usage

It only needs air to cool the coil. Therefore, you don’t need to pay extra costs and labor for liquid-level checking, oil testing, oil recycling costs, and dielectric testing for moisture absorption. Because they are almost maintenance-free, there are no oil leaks when operating, which require gasket replacements.

3. Safe and environment friendly

Cast resin transformers do not create any risk for oil leaks and environmental pollution. During normal operation, transformer explosions are highly unlikely due to utilizing self-extinguishable non-toxic substances, even having external fires. They are also suitable for heavy condensation, wet and polluted environments. The transformers may also withstand abrupt environmental changes from -25ºC to +40ºC in a short time.

TIP: You should ensure that your preferred manufacturer has passed/ obtained C2/E2/F1 tests according to IEC 60076-11 or ISO 17025 like Vietnamtransformer.

Quality certifications of MBT

4. Low-cost installation and lower load losses

There are almost no restrictions when on the installation site. The closer the transformer is to the load, the lower the cable losses and cost.

Reliability: Cast resin transformers have a life cycle of more than ten years and a low failure rate when operated within its designed parameters. This makes it a highly reliable component that is suitable for any electrical infrastructure. You can contact Vietnamtransformer for more information about the cast resin transformer.

5. Low maintenance cost

Cast resin transformer only needs air to cool, and liquid testing becomes unneeded. Its smooth coil surface eliminates massive dirt build-up, even in the most extreme circumstances. You only need technical personnel to clean and visually check it.

6. High short-time overload capacity

Cast resin transformers can handle short-time overloads far better than oil-cooled units as the windings of cast resin transformers are encapsulated in resin, so the effects of axial and radial forces under high current loads are eliminated.

7. Crack-resistant

Historically, the cracking of cast resin transformers shorter life cycles, so the latest technology has introduced glass fiber reinforcement in the windings that eliminate cracking by its heating and cooling curves.

8. Low noise levels

Due to flexible winding supports and design flux densities, they reduce the noise levels during operation.

9. Compact design

By the nature of the design, cast resin transformers are more compact so that they require less space than oil-cooled units.

10. Sustainable

Cast resin transformer contribute to saving our natural resource. Their structure and operation are environment friendly.

SOME DISADVANTAGES OF CAST RESIN TRANSFORMER

On behalf of advantage, there are some disadvantages of dry type transformer.

- The dry-type transformer is long-lasting and with less chance of winding failure. But once it fails, the whole structure of them changed, i.e., a complete change of high voltage and low voltage winding with the limb.

- For the same power and voltage rating, a dry-type transformer is more expensive than an oil-cooled transformer.

- The dry-type transformer is hard to damage, but when damaging, you face difficulty fixing it and having to buy another one.