What is transformer specification - important specs in a transformer

IMPORTANT TRANSFORMER SPECIFICATIONS

When we connect with our customer, especially private customers, the acction of supplying specs to us is very important. Someone does not know important transformer specification so they supply us too little information, it make the time for quotation become longer.

In this article, i will list some important transformer specs commonly used in every country. It plays a central role in transformer price. Some customers need more accessories like VCB, Fan,… It would be best if you gave us the name so that we can design it for you.

Table of content

1. Transformer types – transformer specifications

2. Winding connection- transformer specifications

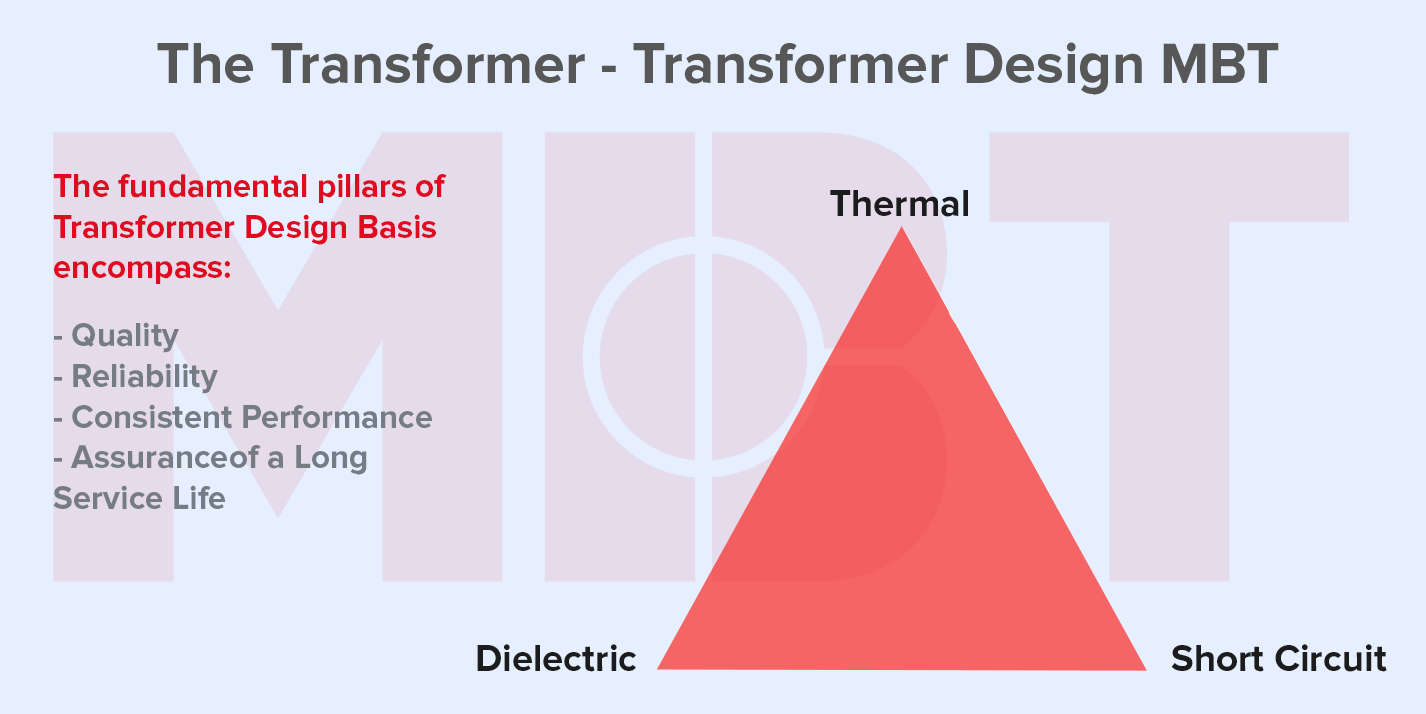

3. No-load loss/ short circuit loss or efficiency

6. Primary voltage/ secondary voltage

1. Transformer types – transformer specifications

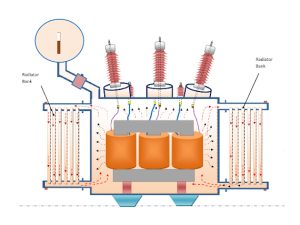

There are many types of transformer in the market. Depending on your demand and your project, you can choose dry type transformer or oil type transformer. In some challenging weather conditions, dry type transformer may be the best option. Of course, the price of a dry-type transformer is always higher than an oil-type transformer.

If you choose an oil-type transformer, we offer you two options: Open-type transformer and sealed type transformer. Open types one, have an auxiliary oil tank and sealed type have not. In terms of aesthetics, sealed-type transformers are highly recommended compared to open-type transformers. Besides, this device also ensures environmental safety. Therefore, sealed type transformers are often used in urban areas, cities, residential areas without affecting the aesthetics and environment. Meanwhile, because the design is somewhat cumbersome and frightening, the open-type transformer is not as aesthetically pleasing as it is, but occupies a lot of ground area.

2. Winding connection- transformer specifications

In three-phase transformers the windings can be connected together in a star (Y), triangle () or zigzag pattern. When connected in star, we take three terminals in common and the other three ends to be free (figure a), connect in triangle, then the end of one phase is connected to the other end (figure b). When each phase zigzag's winding is divided into two halves and wound on two different cylinders, the two halves are connected in reverse series (figure c).

The zigzag type is rarely used because it costs more copper and is only used in rectifier transformers or in measuring transformers to correct the error of phase displacement.

3. No-load loss/ short circuit loss or efficiency

Power loss in the transformer = no-load loss + short-circuit loss

Inside:

– No-load losses or losses in the ferromagnetic core of the transformer, regardless of the current flowing through the transformer

Short-circuit losses or losses in the copper winding of the transformer, depending on the current flowing through the transformer: deltaPcu = RI ^ 2 = U ^ 2 / R

(R is the resistance part of the copper coil)

To reduce the power loss through the MBA, we must reduce the voltage U put on the transformer -> Avoid the transformer under load!

Related article: losses in transformer

4. Applicable standard

A standard transformer always has 3 types of certifications: IEC 60076- 2015, ISO 9001- 2015, ISO 14001-2015.

Depending on the country/customer, some countries or customers need more than that like a Type-test certificate (From KERI lap with MBT transformer) or OHSAS 18001-2015.

Before you want to buy a standard transformer, you should ask your site engineer about the applicable standard in your transformer in order to make sure that it can work well in your environmental condition.

Related article: power transformer manufacturer

5. Rated power

Transformer rating is the amount of electricity that the machine can convert for the load behind it. Since a transformer (transformer) has only the function of transmitting and distributing power, not an energy conversion device such as an electric motor, the transformer's rating is in units of kVA, not kW. When transmitting the power, the machine's power has 2 components: reactive power kVA and active power kW.

Machine capacity is a technical index to choose a suitable machine for load requirements to avoid unnecessary waste while ensuring the machine's long-term working modes.

6. Primary voltage/ secondary voltage

Transformer primary voltage.

Primary voltage is the voltage applied to the ends of the primary winding of the transformer. The energy supplied to the primary winding must be in the form of a variable voltage, producing a constantly changing current in the primary, since only a changing magnetic field will induce a current in the secondary. A transformer consists of at least two sets of windings wound on one magnetic core. There are two main purposes for using a transformer. The first is to convert the energy on the primary side to another voltage level on the secondary side. This is done using a different number of turns on the primary and secondary. The voltage ratio is the same as the turn rate. The second purpose is to isolate the power source from the destination, personal safety, or create a voltage difference between the source and the load.

If the primary has less turns than the secondary, you have an upgraded transformer that increases voltage.

If the primary has more turns than the secondary, you have a step-down transformer that reduces the voltage.

If the primary has the same number of turns as the secondary, the output voltage will be the same as the input voltage. This is the case with an isolation transformer.

Secondary voltage transformer.

Secondary voltage is the coil that supplies the output voltage. The output voltage of a transformer varies with different load resistances, even with constant voltage input. The degree of variation is influenced by the inductance of the primary and secondary windings which, among other factors, are equally important including the winding resistance and the degree of mutual inductance (magnetic coupling) between primary and secondary windings. For source transformer applications, where the transformer is loaded as a constant voltage source, the secondary voltage should be changed as little as possible for large differential load currents. The measurement of a transformer's efficiency maintaining a constant secondary voltage over a current load range is known as the transformer's voltage regulation. It can be calculated using the following formula: "Full load" is the moment at which the transformer operates at its maximum permissible secondary current.

This operating point will be determined primarily by the winding size and the method of transformer cooling. One main reason to change the secondary voltage is to compensate when the incoming line voltage changes. The secondary load base voltage will be constant, or adjusted, if the line voltage fluctuates by using the automatic device. A voltage tolerance limit is maintained to avoid constant voltage hunting, usually between half a volts and several volts. A transformer is an electrical device consisting of two or more windings connected by a flux. If a voltage is applied to the first coil, a flux is generated. If the magnitude of the flux applied changes, the produced flux will change as well. This changing flux will link the primary and the secondary and induce a voltage across the secondary. The concept of voltage induction on the secondary winding using the varying voltage in the primary is called mutual inductance or bonded flux.