Visual Inspection of Transformers/ MBT Transformers

Visual Inspection of Transformers

Visual inspection is an important part of maintaining the transformers. It shows the key condition information.

For example, misplaced valves, stuck temperature gauges, plugged radiators, and level gauges, noisy oil pumps, or fans. Oil leaks can often indicate possible oil contamination, loss of insulation, or environmental problems. Physical inspection requires personnel experienced in these techniques. Some required physical examinations will not be covered here as they have been addressed previously. Be sure to check the following: winding temperature indicator, pressure relief device, surge pressure relay, tank, breathing tube, and relay.

Table of content

1. Leaks

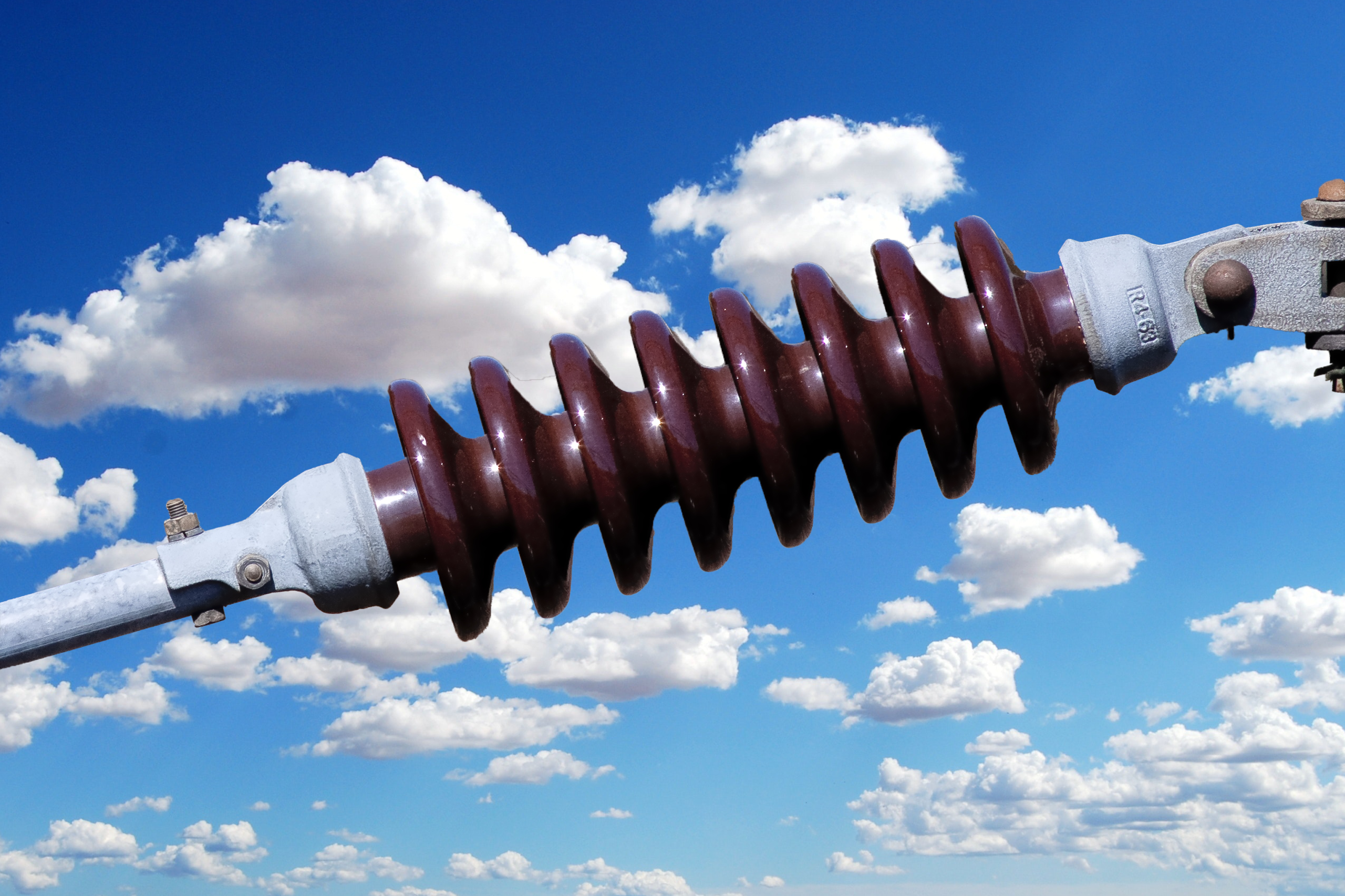

There are some common areas to easily develop leaks such as welding points, bushings, gauges, and de-energized tap changer handles. The best way to search for these leaks is by checking the pressure or vacuum gauge.

Although a transformer doesn’t have any moving parts, its windings do vibrate. Therefore, bolts can be loosened and there are leaks around inspection plates, bushings, and other bolted areas.

The transformer oil expands as it gets hotter and contracts as it cools, which means a sealed transformer will have pressure or a vacuum.

2. Paint condition

When inspecting the transformer’s paint, there are some following issues:

- Rust – formed by deteriorating metal and then eventually causes leaks and pinholes.

- Peeling – caused by moisture accumulating under the paint surface and causing flaking.

- Cracking –caused by paint inevitably hardens and becomes brittle over time. Temperature changes in the metal, which causes it to expand and contract, can also lead to this issue.

- Caulking –the white, chalky film mentioned earlier that develops on the paint due to sun exposure.

3. Gauges

Typically, a transformer will be equipped with 3 gauges: temperature, level, and pressure/vacuum.

Level Gauge

The readings of the level gauge are for high, low, and 25%. It is necessary to measure the level accurately, operators should read the both temperature and level gauges. The level is normal If the temperature gauge says the transformer is operating at 25°C. If the temperature gauge reads 85°C, this level would be low. Oil expands as it heats up and contracts as the oil cools down. On a well-sealed unit, this is how you get vacuums.

Pressure/Vacuum Gauge

The transformer is well sealed, you will get pressure (right side of zero) and vacuum (left side of zero). These vacuum cleaners are often related to temperature. Ambient temperatures can be cold enough to cause vacuum conditions in early fall and winter. These temperature changes create vacuum and pressure. Remember that the vacuum and pressure on the transformer indicate that we have a well-sealed transformer, indicating no leaks.

Never attempt to sample a transformer in a vacuum. This will result in air bubbles being sucked into the transformer, which can become trapped in the windings and cause problems. Before sampling, you must reduce the vacuum with dry air or nitrogen. This standard list three types of nitrogen that can be used. Type 3 is the driest N2 type and is more popular.

Temperature Gauge

Two different types of temperature gauges are Oil and winding temperature gauges. When performing visual inspection during oil sampling, provide the laboratory with the highest temperature of the oil. Some temperature gauges have drag arms. If operators reset the drag arn, they will indicate the highest temperature the transformer has reached. The life of the transformer will be shortened due to high temperature. Some transformers have a thermostat that will turn the fan on and off as needed.