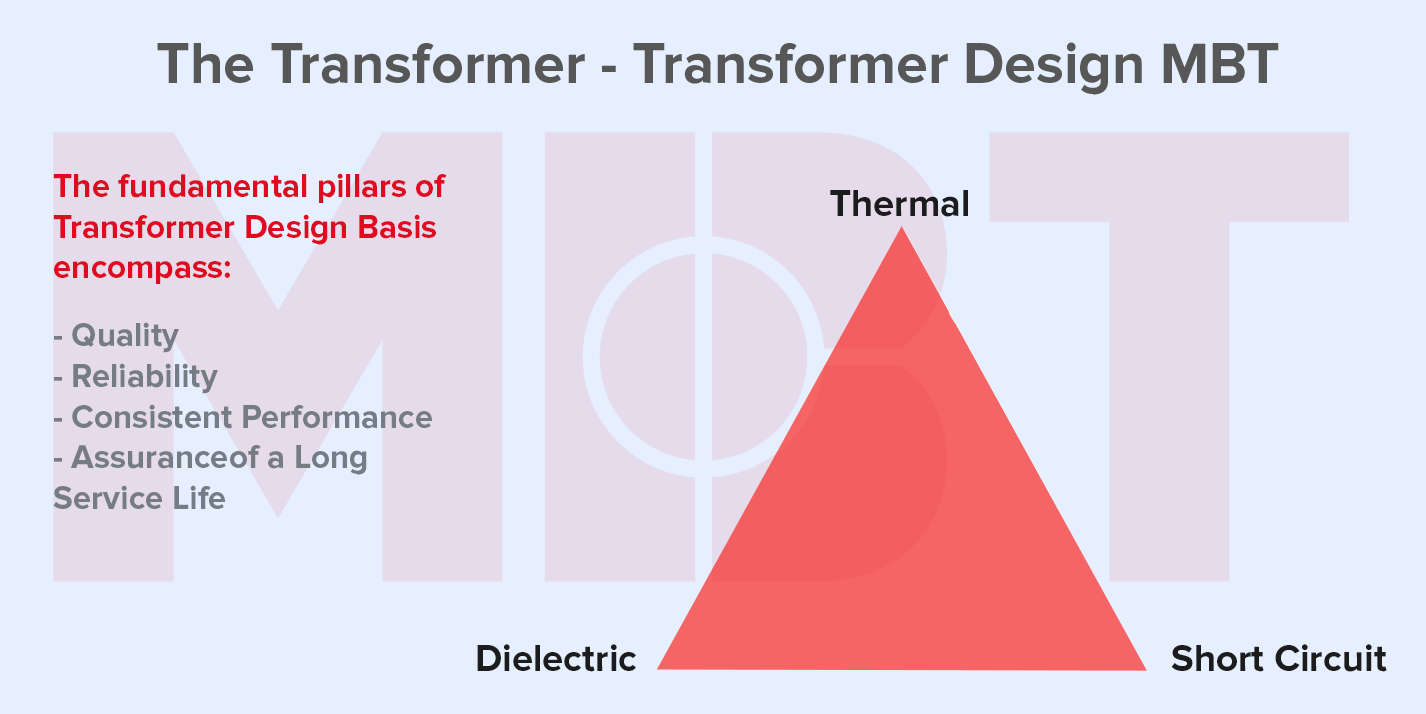

Transformer core- Definition- Construction- Transformer core types

Table of content:

2. The role of transformer core

3. Working principle of transformer core

4. Types of transformer core? Materials of transformer core

1. What is a transformer core?

First of all, we need to know about the transformer. Transformer is a device working under the principle of mutual induction. Simply, mutual inductance is a linkage between two transformer windings. The magnetic flux appear and go through a structure called the transformer core. You can see transformer core in this image:

Transformer core

In the magnetic circuit, transformer cores are the main path. When comparing transformer core to electrical circuit, we can say it as the conductor.

The conductor carries the current in the electrical circuit and and the magnetic circuit, transformer cores carry the magnetic flux.

The transformer core has less reluctance. Reluctance opposes the flow of magnetic flux. So That transformer core should have less reluctance.

Because reluctance opposes the low of magnetic flux, the transformer core has less reluctance.

MBT transformer core

2. The role of transformer core

Transformer core is the most important part of a transformer. Its a static device that transmits power from one source to another source through the principle of electromagnetic induction. It's made from pieces of magnetic material with a high magnetic permeability. These pieces are used to guide magnetic fields in transformers.

3. Working principle of transformer core

Basically, transformer core is the main part of a transformer, but its not work alone. Its combine with two coils according to Faraday’s law of electromagnetic induction and mutual induction.

Working principle of transformer core

On the transformer core, there are usually two coils: The primary coil and the secondary coil. The core laminations of the transformer are joined in the form of strips. The coils have high mutual inductance.

Start with the primary coil, when an alternating current passes through it, its creates a varying magnetic flux. As per Faraday’s law of electromagnetic induction, this change in flux produces an emf (electromotive force) in the secondary coil that is linked to the core with the primary coil. This is mutual induction.

4. Types of transformer core? Materials of transformer core

4.1 Types of transformer core

According to projects, transformer core are made of many different materials, and several types. Here are some specific types of transformer core:

-

Steel Laminated Cores: These types of transformer cores are known for their ability to penetrate, reduce magnetizing currents and are suitable choice for use in voltage transmission in the audio frequency level.

-

Solid Cores: The solid cores have the highest electrical resistance and magnetic permeability. They are commonly used in electrical transmission, where the frequency is high and requires smooth and safe performance. In nature, these types of cores are solid, they have a long-serving life.

-

Toroidal Cores: Because of the circular design, the toroidal cores are used as an inductor in electric circuits. They are effective in handling a high level of energy load.

4.2 Types of magnetic core materials for transformers?

Electrical transformers have primary, secondary and tertiary windings. They are driven by the flux between the windings. Magnetic cores serve as the pathway of the flux. It can be made from the following types of materials:

-

Amorphous Steel: Amorphous steel cores are made from several paper-thin metallic tapes, which help reduce the flow of eddy currents. They have few losses and can easily operate at high temperatures. The amorphous steel cores are most commonly used in high efficiency transformers operating at medium frequencies.

-

Solid Iron Core provides magnetic flux, helping retain high magnetic fields without iron saturation. It is not used for transformers operating at AC applications, because of large eddy currents produced by the magnetic field. They produce heat at high frequencies.

-

Amorphous Metals: They are also known as metals, these metals are glassy or non-crystalline. Amorphous are used for creating high-performance transformers. Because the materials have low conductivity, they help reduce eddy currents.

-

Ferrite Ceramics: Made from iron oxide and one of multiple metallic elements, ferrite ceramics are a class of ceramic compounds. They apply for high-frequency applications. Ceramic materials serve as efficient in insulators and help decrease eddy currents.

-

Laminated Magnetic Cores: These cores are made from iron sheets, covered with an insulating layer that prevents eddy currents.

-

Carbonyl Iron Cores: The cores are made from powdered carbonyl iron. They provide table service across a wide range of magnetic flux and temperature levels. The cores feature small iron spheres coated with a thin insulating layer. It has the role of reducing the effects of eddy currents at high temperatures and temperature levels.

- Silicon Steel: The steel has high electrical resistivity. The silicon steel core provides stable performance for many years and offers hight saturation flux density.