The important role of the transformer maintenance

The Important Role of the Transformer Maintenance

The purpose of transformer maintenance is to ensure all parts of the transformer and accessories be kept in good condition. In addition, another purpose is to maintain a historical record of the condition of the transformer.

Transformers can be maintained periodically or as condition-based maintenance. The latter is usually the most economical way of doing maintenance.

Maintenance is recommended based on some steps as follows:

– Inspections

– Analysis of oil samples

– Electrical measurements

– A test of equipment

– Measurement of temperatures by using a heat-sensitive camera, and monitoring (offline and/or online).

Table of content

1. Maintenance in energized condition

2. Maintenance in de-energized condition

1. Maintenance in energized condition

When the transformer is in operation, operators should limit to do maintenance activities to avoid human accidents

After taking necessary safety precautions, the following maintenance can be done in energized condition:

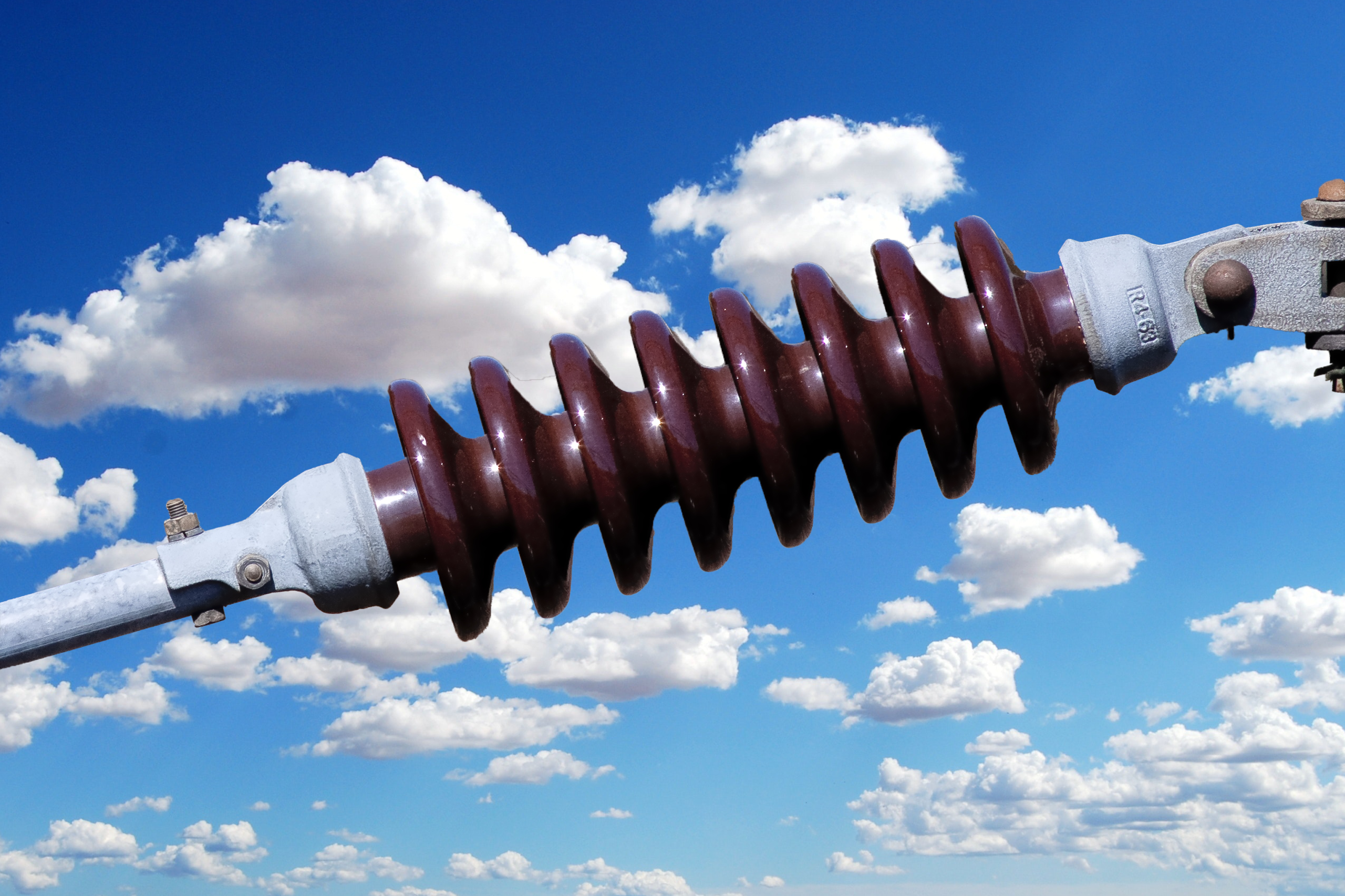

- Inspecting for leakages, and cracks in porcelain bushings, checking auxiliary equipment, etc.

- Checking drying material in the dehydrating breather (conservator type only).

- Measuring temperatures of joints, bushings, etc. by using a heat-sensitive camera.

- Oil samples (conservator type only).

2. Maintenance in de-energized condition

Before maintaining the transformer, It has to be disconnected from the network and earthed. When the circuit breaker and the isolator have been opened, they shall be locked in an open position to prevent inadvertently closing during maintenance work.

Items to be considered are:

- Bushing gaskets; if the gasket has lost its elasticity, it must be replaced, if there are leakages, tightening usually will help. The reason for loss of elasticity could be excessive heating or aging.

- Cover gaskets, valves, and gaskets of the tap changer. If there are leakages, bolt tightening will often help,

- Welded joints. Leaking joints can be repaired only by welding.

- Cleaning contaminated bushings (cleaning agent e.g. methylated spirit),

- Functional inspection and testing of applicable accessories,

- Tap-changer maintenance,

- Move the tap changer through all positions a few times, all types of tap changers,

- Oil and insulation maintenance, drying and reclaiming,

- Liquid sampling from the bottom drain valve for larger units as required,

- Check to dry material in the dehydrating breather. (Conservator type only),

- Amend surface treatment defects,

- Cleaning glasses on the gas relay, thermometer, and liquid level indicator,

- Inspection and maintenance on the active part should not be performed unless there are unambiguous indications of defects.

In addition, for dry-type transformers:

- Inspection and e.g. vacuum cleaning as required,

- Tightening winding supports.

- Humidity removal,

- In heavily contaminated installations more frequent inspections may be needed.