Features of Dry-type transformer/ cast resin transformer

Dry-type transformers or cast resin transformers eliminate an important disadvantage of oil transformers, which is the risk of fire or explosion. It is therefore an inevitable problem to find a way to eliminate that potential risk: to build an oil-free transformer, which experts are accustomed to calling dry-type transformers.

Table of contents:

1. The idea of manufacturing dry-type transformer

2. Features of dry-type transformer

3. The advantages of dry-type transformer

4. Dry-type manufacturer in Vietnam

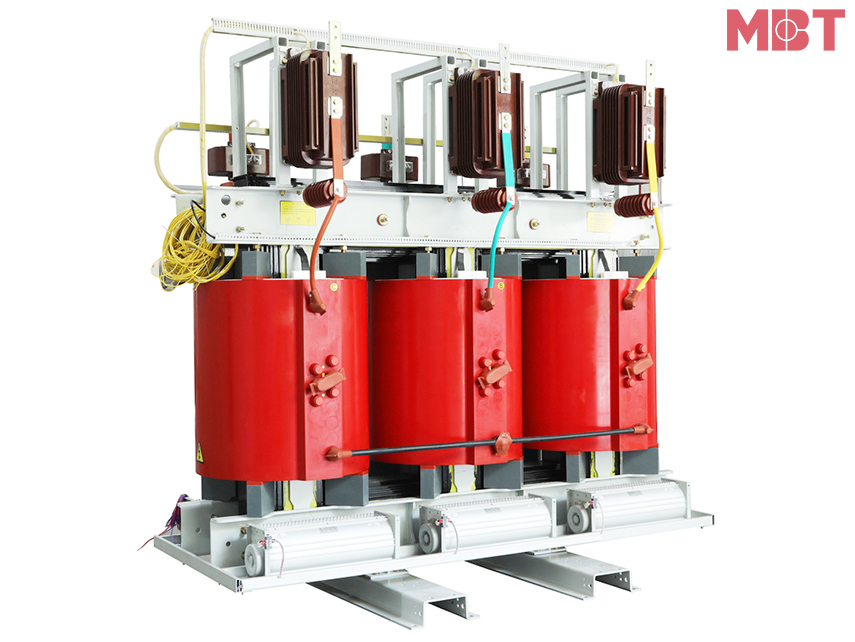

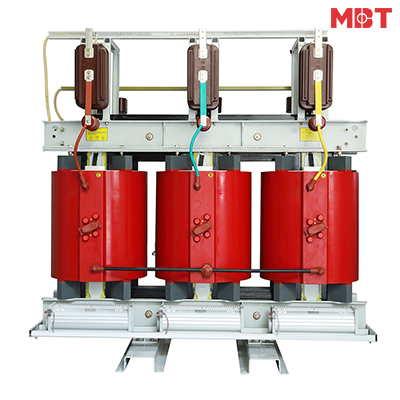

MBT Dry-type transformer

1. The idea of manufacturing dry-type transformer

Actually, the idea of manufacturing dry-type transformers existed from the first half of the last century, but at that time, conductive materials, electrical insulation, magnetic steel ... the protective equipment, metering and control were backward. They didn't allow the development of dry-type transformers as in recent years. Today, dry-type transformers are used commonly.

2. Features of dry-type transformer

- Thanks to the fabrication of silicon corrugated iron with low Fuko current loss combined with the use of copper coils, ladder steel cores, small gaps, low noise does not cause environmental pollution. current oil transformers (noise of oil transformers at a distance of 1m is usually approximately 80db, causing harm to the health of surrounding people). The optimal design of the computer-dry-type transformer elements adds to its advantages: significant energy savings by reducing magnetic steel losses (Fuko current no-load and copper losses, load loss), the transformer operates with low noise.

- Thanks to the computer-based design, the selection of parameters is optimized, the technology of silicon steel fabrication, impregnation paint is increasingly modern, the measurement, control and protection system is increasingly complete, so the reliability. dry-type transformer reliability and very long life.

Dry-type transformers meet EU environmental standards HD484 for climatic conditions (C0, C1, C2), environmental (E0, E1, E2) and fire resistance (F0, F1, F2).

- The capacity of the dry-type transformer is quite large. Dry power transformers for distribution systems are built with capacities between 50 and 2,500KVA, dry power transformers with capacities between 10,000 and 20,000KVA / 35KV and in the public future. productivity will be even greater.

- Dry-type transformers are widely used in power distribution systems, self-use systems of power plants, excitation systems, locomotive power supply systems running on railways, subways, homes nuclear power machine. dry-type transformers are also popularly used in hotels, stadiums, petrochemical plants, airports, and drilling rigs and especially where there are strict fire protection requirements.

- Dry-type transformers are capable of withstanding an overload. For places where the load is not uniform during the day, such as lighting electricity, cultural areas, air-conditioners, etc., the capacity of the dry-type transformers is smaller than the load to take advantage of the overload capacity of the them. The main service time of a transformer will be over or under overload. Using dry-type transformers it is possible to reduce their spare capacity or reduce the number of spare dry-type transformers.

In today's electrical systems, for every KW of power source capacity, about 5 - 6KVA transformer capacity is required. Total electrical losses in transformers account for nearly 30% of all electrical losses in the grids.

Therefore, transformers are one of the major components of electrical systems, crucial to their economy.

By the end of the 20th century, almost all transformers were of the type of oil transformers, in which the oil played a role both to help cool the windings and increase their insulating strength.

Oil quality directly affects the reliability and service life of the transformer. During operation, it is necessary to regularly monitor the oil condition to promptly detect changes in oil properties through the determination of a series of important parameters such as mechanical impurities and suspended carbon, insulation durability, acid index, flash temperature of oil, viscosity, transparency, stability, dielectric loss angle ... To manage oil quality, it is necessary to have many technical means, it is necessary to have good managers, technicians, processing workers with high skills ... On the other hand, with a large number of oil transformers, the risk of fire and explosion is always permanent, threatening equipment failures and causing accidents to people, polluting the surrounding environment.

In the 50s of the last century, a number of countries switched to using some anti-fire and explosion-proof oils. Most of which is very toxic and non-biodegradable. Since 1970 the above oil has been banned for use because its toxins adversely affect human health and the environment, even when the oil is inherently very small in conventional transformer oil.

3. The advantages of dry-type transformers

In addition to being less prone to fire and explosion like oil transformers, dry-type transformers also have many other outstanding advantages:

Economically: dry-type transformers have a longer lifespan than some other transformers. And the ability to install and move is also convenient and easier. Cable costs and cabling losses can be reduced when installed near the load.

Dry-type transformers are capable of working in harsh environments and resistant to fire.

- Dry-type transformers have a rather large working capacity, have higher capacity to distribute electricity to public places.

- For uneven distribution load centers, dry-type transformers can be used to take advantage of their overload capacity.

- Dry-type transformers are also extremely friendly to the surrounding environment, always providing safety and minimizing pollution

The working time of dry-type transformers is usually longer than that of oil-immersed transformers

4. Dry-type manufacturer in Vietnam

MBT is a Vietnam manufacturer of transformers. In 2021, we launch our cast resin transformer lines which meet international standards ISO 9001-2015, ISO 14001-2015, IEC-60076,... Our dry-type transformers are ready for export to all around the world by the end of 2021. If you need consultations, quotation for your projects at the end of 2021, please contact us via hotline: +84 913006538 and email: info@mbt.vn